Choosing the right mini excavator parts can make or break the success of your project. The wrong choice can cause your project to perform anciently or cost you additional money. In this article, I’ll help you make a good choice by reviewing the essential parts and what you need to know to pick the best mini excavator parts for your project.

When selecting mini excavator parts, it’s important to consider your project requirements, the durability and quality of each part, and compatibility with your machine. This article provides detailed information to help you choose the right parts, ensuring efficiency and minimizing costs.

Now, let’s go through how to pick the best mini excavator parts for your needs.

Table of Contents

Toggle1,How to Identify the Right Mini Excavator Parts for Your Project?

To identify the best mini excavator parts for your project, we need to understand the requirements of your project and machine, so you can pick the parts that work best for your project. Whether you’re doing excavation work in tight spaces, moving heavy loads, working in a harsh environment, or doing other applications choose the correct parts to increase your operation efficiency and the life of the machine.

To identify the right parts, look at the application, terrain, the load requirement, and also how long you have to complete the project which will help you choose the right parts to do the best job for the cost.

First, understand what your needs are on the job site. For example, if you’re working in very tight urban spaces, then compact tracks, a smaller bucket, and a short arm are ideal. If you’re doing heavy lifting, then get reinforced hydraulics and a heavy duty undercarriage. Make sure the parts are compatible with your machine’s specifications. If you have a smaller mini-excavator with a smaller engine, you have to have smaller parts that are more fuel efficient and don’t strain the hydraulic system.

Table: Factors to Consider When Identifying the Right Parts for Your Mini Excavator

| Factor | Considerations |

| Project Type | Excavation depth, load size, and space constraints |

| Terrain | Hard ground vs. soft or uneven ground, which affects track and bucket choice |

| Load Requirements | Engine power, hydraulic strength, and bucket size for handling heavy materials |

| Duration | Longevity of parts, durability in continuous operation |

| Compatibility | Ensure parts are compatible with your specific mini excavator model |

2, What Are the Parts of a Mini Excavator?

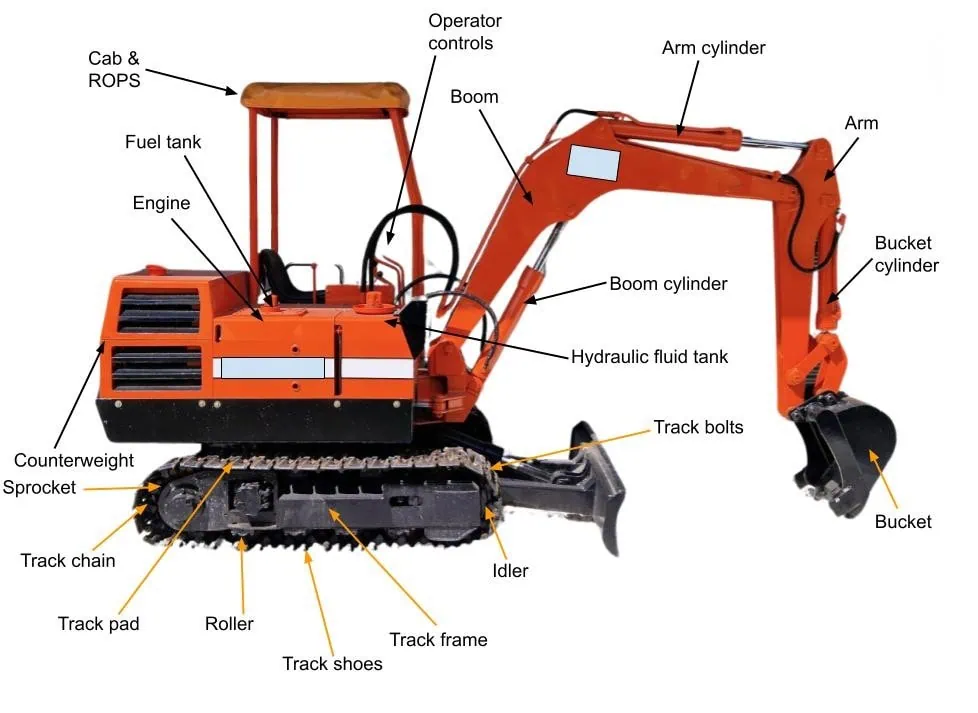

A mini excavator has multiple parts, all with a specific function to help set the machine up, run the machine, or provide a backup option in case something goes wrong. Understanding these parts on a mini excavator will give you insight into what they do and help you decide which parts you need to change or upgrade based on your project requirements.

Six main parts make up a mini excavator: the engine, undercarriage, hydraulic system, bucket, boom, and cabin. Each part works together to operate the machine and help you get your work done.

Let’s break down the essential mini excavator parts:

Engine: Provides power for operation and ensures efficient movement and digging.

Undercarriage: Supports the weight of the machine and helps it move across various terrains.

Hydraulic System: Powers the arm and bucket for lifting, digging, and other tasks.

Bucket: The primary digging tool, available in various sizes for different types of excavation.

Boom & Dipper Arm: Extendable arms that control the depth and reach of the bucket.

Cabin: The operator’s seat, where the control systems and comfort features are housed.

Table: Main Parts of a Mini Excavator

| Part | Function |

| Engine | Powers the excavator for movement and hydraulic systems. |

| Undercarriage | Provides mobility and support for the machine. |

| Hydraulic System | Powers the boom, bucket, and other attachments. |

| Bucket | Used for digging and lifting materials. |

| Boom & Dipper Arm | Extendable parts that allow the machine to reach greater depths. |

| Cabin | The operator’s station, equipped with controls and comfort features. |

3, What Are the Basic Parts of an Excavator?

Even though mini-excavators are tiny versions, they share many of the same parts as the big boys. All of these parts work together to run the machines and help you do whatever it is you do with a mini-excavator.

Some of those key essential parts include the engine, undercarriage, hydraulic system, boom, bucket, arm, and cabin. Being familiar with these parts and how they’re used will enable you to maintain and replace the parts you come in contact with.

The main parts of any excavator, mini or full-size, include:

Engine: Powers all of the machine’s movements and operations.

Tracks/Wheels: Allow for mobility across different surfaces and environments.

Boom and Dipper Arm: Work together to dig, lift, and reach into tight spaces.

Bucket: A key component for digging and scooping materials.

Hydraulic System: Powers most of the machine’s operations, from arm movements to bucket lifts.

Cabin: Houses the operator and controls the machine’s movements.

Without these basic parts, the excavator couldn’t do the general digging, trenching, scooping, or whatever job you needed it to do. The catch comes in the fact that you might need specialized parts or an upgraded version of one of these basic parts, depending on the type of work you want your mini-excavator to perform.

Table: Basic Parts of an Excavator

| Part | Function |

| Engine | Provides power to all excavator operations. |

| Tracks/Wheels | Essential for mobility and stability. |

| Boom & Dipper Arm | Used for reaching and digging at varying depths. |

| Bucket | The primary tool for excavation and material handling. |

| Hydraulic System | Controls the movement of the arm and bucket. |

| Cabin | The operator’s area for controlling and monitoring the excavator. |

4, What Are the Key Factors to Consider When Choosing Mini Excavator Parts?

When you select those parts, you have a few things to think about. You want to make sure the part you buy works for your mini-excavator; it’s strong enough to do the job you need it to do; the company has a good reputation that stands behind the part because these things aren’t perfect all the time; and there’s a good chance you will think about the environmental conditions this machine will be working in.

Quality, compatibility with your mini-excavator, the environment, and how often you plan to use or abuse the parts in your mini-excavator are all things to consider while shopping. Proper part selection based on these and other factors will mean less downtime and hassle wrenching on your mini-excavator and more money in your pocket.

To select the right parts for your mini excavator, you must first assess the needs of your project. For example, if you are working in an area with heavy loads like rocks or clay, you need a bucket that can handle a beating and have enough hydraulic power to pick up the load. Compatibility is key. Most parts are listed for specific models of mini-excavators. If they aren’t, don’t buy them. You will have problems. Make sure it says it’s a direct replacement for your mini-excavator’s make and model.

If you are using the machine a lot, heavy tracks are a must. The same holds for buckets and engines. Parts to handle that type of work all day are out there. What if you are working in extreme weather? They make tracks, buckets, and engines for that, too.

Table: Key Factors to Consider When Choosing Mini Excavator Parts

| Factor | Considerations |

| Compatibility | Ensure parts match your mini excavator model and specifications. |

| Durability | Opt for durable materials for parts subject to heavy wear. |

| Environmental Suitability | Choose parts that can withstand weather conditions and terrain. |

| Usage Frequency | Frequent use requires more robust and high-quality parts. |

| Brand Reputation | Always consider parts from well-known and reliable manufacturers. |

5, How to Choose the Best Mini Excavator Bucket for Your Job?

The single most important part of a mini excavator is the bucket, and selecting the right one can make a huge impact on how well you can dig. The bucket’s size, strength, and design all matter in how well you can scoop dirt out of the ground.

Select a bucket that suits the type of dirt you plan to work (a third of a yard of rocks is hard to get out of the ground), the size of the load you plan to lift, and the depth of the holes you plan to dig. There are different types of buckets for a reason, such as grading buckets, digging buckets, and/or ditching buckets. Each has a particular use, and for the cost versus efficiency, you want the right tool for the job.

Choose the right bucket for the material you plan to excavate. If you’re moving rocks and hard soil, you need a heavy-duty bucket. If you are working in softer materials, such as dirt, sand, or gravel, a standard bucket bucket will be sufficient. Plan the width and depth of the bucket to match the material you will be digging out of the ground to the depth it will be dug out. A wide bucket moves a lot of dirt if your hole is shallow. If you have to dig down, you’ll move the dirt slower with a wide bucket.

A narrow bucket takes longer to dig the same width of hole, but it’s moving the dirt out better if you are digging deep holes. If you plan to dig in a small or confined space, a narrow bucket will be more efficient. Ensure your bucket will work with your mini-excavator’s hydraulic system.

Table: Choosing the Right Mini Excavator Bucket

| Bucket Type | Ideal Use |

| Standard Bucket | Suitable for general digging tasks in most soils. |

| Wide Bucket | Ideal for moving large amounts of loose material over a wide area. |

| Digging Bucket | Best for deep digging or breaking through hard materials like rock. |

| Clamshell Bucket | Used for precise digging in hard-to-reach areas or underwater tasks. |

6, How Often Should You Replace Mini Excavator Parts?

Knowing when to replace each of these mini excavator parts, beyond fluids and filters, is critical to efficient operation and to avoid finding yourself unexpectedly dead in the water. The replacement cycles for mini excavator parts vary widely based on usage and work terrain as well as the specific mini items.

Any part that receives heavy wear is likely to need replacing every few years. Examples include tracks, hydraulic hoses, and the bucket. Regular inspections help you recognize when it is time to replace something because it’s worn out and not serving the purpose for which it was designed.

Mini excavator parts wear out at different rates depending on how often you use them and the conditions under which you use them. Things like undercarriages and tracks may only last two to three years. Especially if you use your mini excavator a lot in rough conditions, you may find yourself putting new tracks on every couple of years. Inspect hydraulic components and seals regularly for leaks or wear. Be diligent in watching engine oil and hydraulic oil for bad smells and contamination.

Traces of coolant or metal contaminants will shorten the life of many of your mini excavator’s parts. Regular inspections and a defined maintenance schedule will save you money. Keep an eye on your investment’s health. Replace parts as necessary rather than waiting until they tear up other parts of the machine.

Table: Replacement Frequency for Mini Excavator Parts

| Part | Replacement Frequency |

| Tracks | Every 2-3 years, depending on usage and terrain conditions. |

| Hydraulic Hoses | Every 2-4 years, or sooner if cracks or leaks appear. |

| Bucket | Depending on usage, the bucket may need replacement every 3-5 years. |

| Engine Filters | Replace every 1000-1500 hours of operation. |

| Seals and Hydraulic Fluids | Inspect regularly, replace every 2 years or sooner if contaminated. |

7, How to Maintain Mini Excavator Parts for Longevity?

Many of you have chosen and learned with us in our Soil and Rock Online Course. I’m proud of you for taking that next step to invest in yourself and your business. Always remember, there is a cost to owning a machine. Standard upkeep means that most of your mounts work as long as possible, the way we like it and without costly breakdowns.

Maintain your mini excavator parts. Keep the dirt, mud, and sticks cleaned off. Keep parts lubricated according to the service maintenance specified in the manual. Keep parts inspected and adjusted. The longer they work, the better they work for you until the end of the job.

Knowing how to select the right mini excavator parts can mean the difference between finishing or NOT completing a project. And mini excavators are marvels of modern engineering. They can ache, lift, and dig in places where you can barely stand, but they still are not perfect. If something breaks or wears out, KABOOM, that little bad boy is down for the count. Use these tips when picking the right mini excavator parts to keep your machines moving, keep those mini excavators making you money, and keep you doing what you do best.

Table: Essential Maintenance Tips for Mini Excavator Parts

| Maintenance Task | Frequency |

| Clean Undercarriage | After every use to prevent soil build-up. |

| Inspect Hydraulic System | Every 100-200 hours, or if you notice performance issues. |

| Lubricate Moving Parts | Monthly or every 100 hours of use. |

| Inspect Engine Filters | Every 500 hours or annually. |

| Check Tracks and Wheels | Every 300-500 hours, depending on conditions. |

8, How to Choose the Right Mini Excavator Parts for Different Terrain?

How to select the right mini excavator parts is the difference in finishing your project or not. These beautiful mini excavators can ache, lift, and dig in places you can’t stand, but they’re not perfect. If something goes out on them, Boop, the monster’s down for the count. Use these tips next time you need to pick the right mini excavator parts. Keep your machines moving, keep those beauties making you money, and keep doing what you do best.

When selecting mini excavator parts, you need to think about the stress on those parts. Different terrains put different levels of stress on the parts. For example, if you drive over rocky or uneven ground, you need extremely durable tracks. If you work in sand or soft soil and need to dig and move around, you have different parts you have to purchase.

To select the right mini excavator parts, consider the unique demands of your project. Are you working in an urban environment where space is limited? Do you need to lift heavy items to great heights? Make sure the parts you purchase are right for the job and work together with the specifications of your mini excavator. All mini excavators have an engine, hydraulic system, bucket, and undercarriage parts that work together to make them move and dig. All the parts work together to create this incredible monster of a machine.

Table: Terrain-Specific Parts for Mini Excavators

| Terrain Type | Recommended Mini Excavator Parts |

| Rocky or Uneven Terrain | High-strength steel tracks, heavy-duty undercarriage |

| Soft or Sandy Terrain | Rubber tracks, lightweight buckets |

| Muddy Terrain | Self-cleaning tracks, corrosion-resistant components |

| Urban/Hard Surfaces | Standard tracks, reinforced buckets |

Summary:

Operators know they can dig. They can lift. They can haul. They can do all kinds of things that you can’t do, but they are not perfect. If something goes out on them, the monster is down for the count. Use these ideas the next time you need to pick portable mini excavator parts, keep your machines running, keep those babies making you money, and keep doing what you do best. Contact with us for more information!